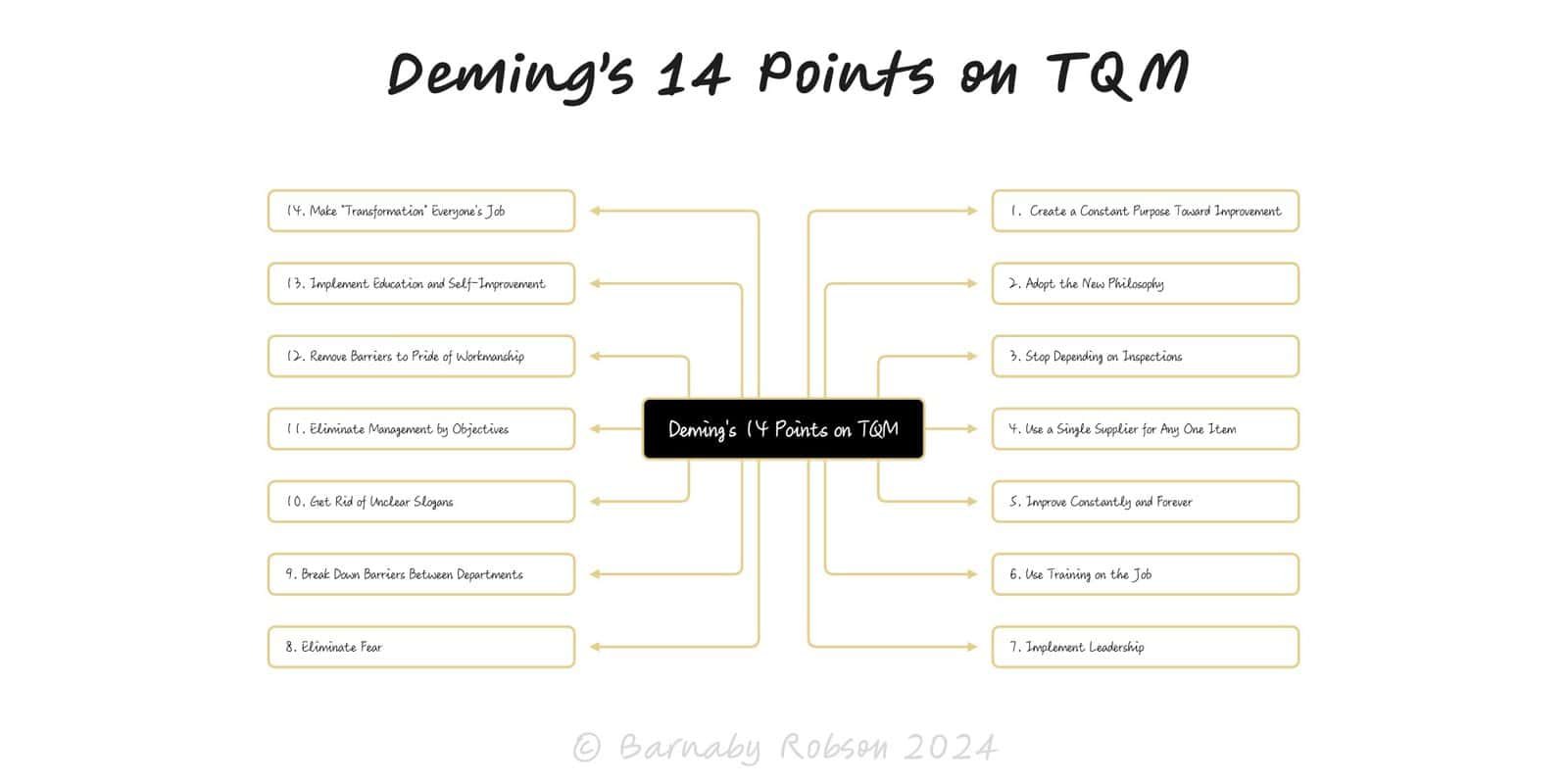

Deming’s 14 points

A management system for building quality into work by reducing variation, improving processes, and aligning everyone to long-term purpose.

Author

W. Edwards Deming

Model type

A management system for building quality into work by reducing variation, improving processes, and aligning everyone to long-term purpose.

W. Edwards Deming

Shaped by Deming’s work with Shewhart and post-war Japan, codified in Out of the Crisis. Core ideas: manage the system, control variation (common vs special causes), and improve continuously via PDCA.

1. Constancy of purpose – commit to long-term customer value, not quarter-to-quarter fixes.

2. Adopt the new philosophy – quality as a management duty, not inspection’s job.

3. Cease dependence on inspection – build quality in; prevent rather than sort.

4. End price-tag purchasing – choose suppliers on total cost and partnership.

5. Improve constantly and forever – continual process and system improvement.

6. Institute training – on-the-job capability building and standard work.

7. Institute leadership – managers remove obstacles and coach.

8. Drive out fear – enable candour and problem signalling.

9. Break down silos – optimise across functions, not within.

10. Eliminate slogans and exhortations – fix systems, not attitudes.

11. Eliminate numerical quotas and targets – manage by process and capability.

12. Remove pride-of-workmanship barriers – fix faulty measures, rework loops, and rating schemes.

13. Institute education and self-improvement – invest in people.

14. Put everyone to work on transformation – led by top management.

Operating model redesign – move from target-driven to system-driven management.

Service excellence programmes – reduce failure demand and rework.

Supplier strategy – consolidate to partnership models on total cost.

M&A integration – standardise leadership, training, and improvement cadence across sites.

Diagnose variation – baseline key flows with SPC; separate common vs special causes.

Clarify purpose – define CTQs and customer outcomes; align metrics to them.

Build-in quality – standard work, mistake-proofing, and training at the constraint.

Redesign management – replace quotas with process measures and visual management.

Partner suppliers – fewer, deeper relationships; shared improvement plans.

Install PDCA cadence – weekly Kaizen, monthly reviews, exec gemba.

Tool obsession – running projects without changing management behaviour.

Inspection theatre – counting defects instead of preventing them.

Target gaming – quotas and league tables that increase variation.

Price-only sourcing – saves today, raises total cost tomorrow.

No exec ownership – the 14 points fail if leadership treats them as a programme, not the system.

Click below to learn other mental models

Before building, map the space: the key forks, dead ends and dependencies—so you can choose a promising path and run smarter tests.

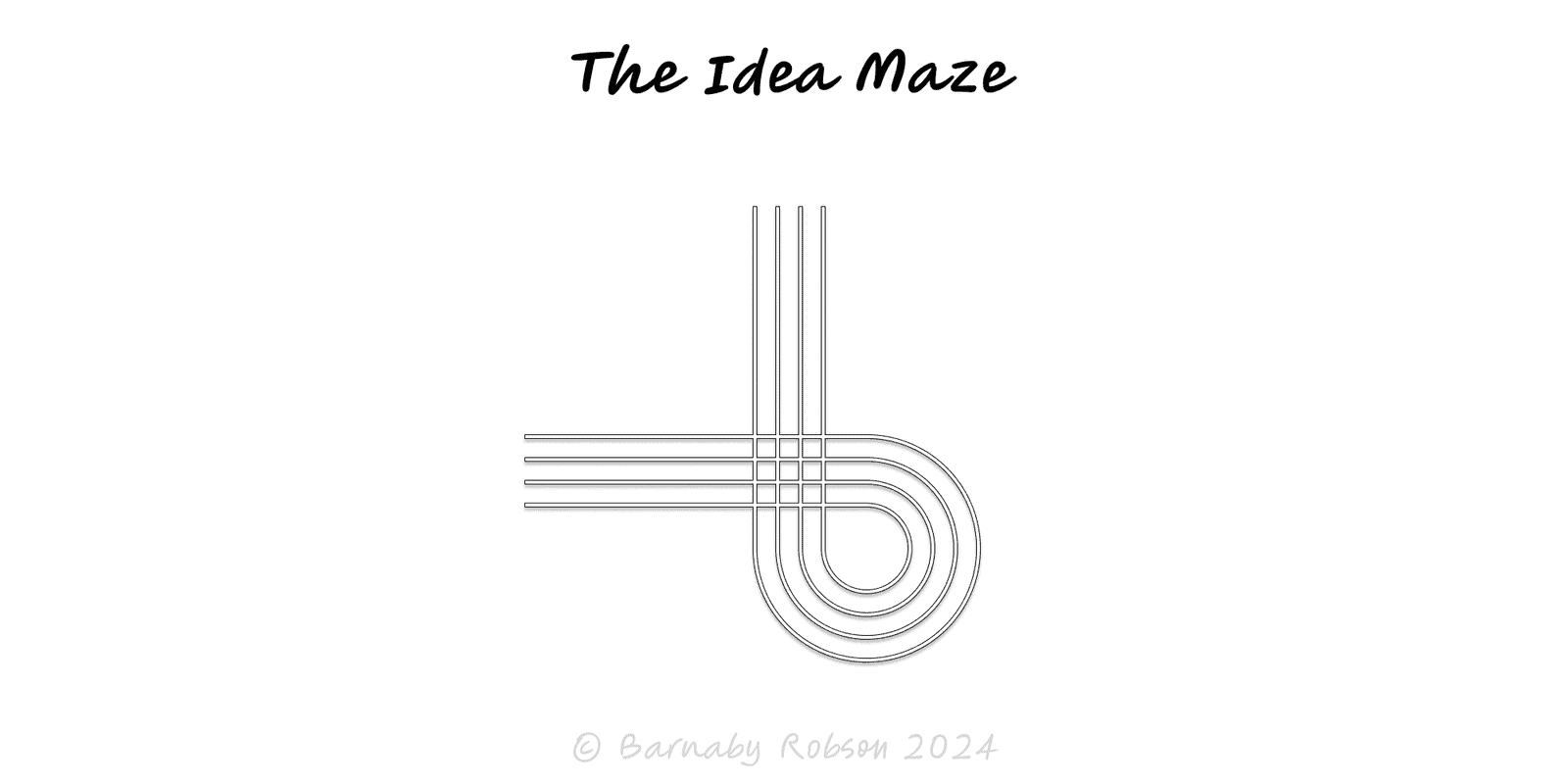

When a rising power threatens to displace a ruling power, fear and miscalculation can tip competition into conflict unless incentives and guardrails are redesigned.

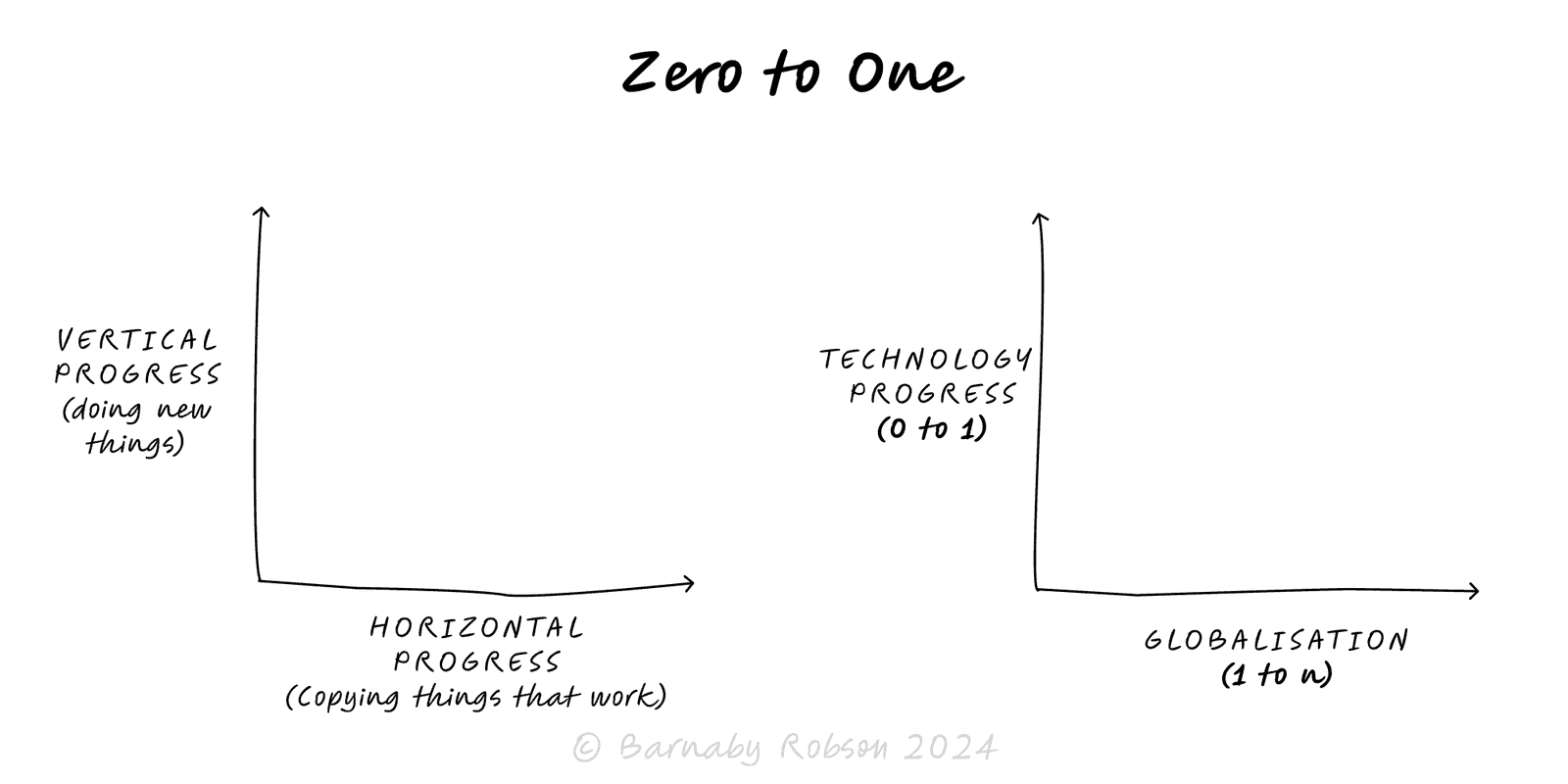

Aim for vertical progress—create something truly new (0 → 1), not just more of the same (1 → n). Win by building a monopoly on a focused niche and compounding from there.